Ash Dewatering & Displacement

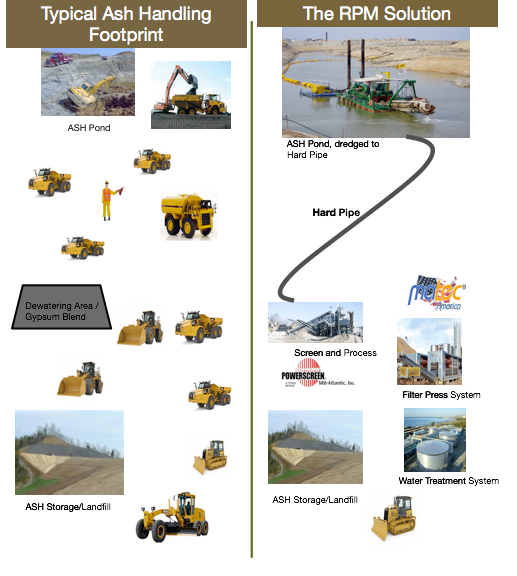

Our ASH Handling Solutions eliminate countless points of control. We do this by reducing the need for heavy equipment and personnel, costly and dangerous material handling, while implementing proven technology to drastically reduce the typical cost to decommission ASH Ponds. Our innovative solutions uses dredging and de-watering methodologies to reduce costs associated with transporting moisture. Our system will allow for limited traffic, liability and time management overruns typically associated with ASH Pond closures. Please contact us to show you how.

- We have partnered with Flash Dewatering Solutions and Matec America to market and operate proprietary Ash Dewatering Filter-presses

- With over 1,800 installations around the world and over 250 in the U.S. the technology is proven

- Designed to turn the liquid ash slurry product into handable “cakes”

- Potential to drastically simplify control and management of Ash associated projects while mitigating risk, cost, and manpower

Footprint Comparison

Ash Dewatering Filter Press Technology

- We have partnered with Flash Dewatering Solutions and Matec America to market and operate proprietary Ash Dewatering Filter-presses

- With over 1,800 installations around the world and over 250 in the U.S. the technology is proven

- Designed to turn the liquid ash slurry product into dry mud “cakes”

- Potential to drastically simplify control and management of Ash associated projects while mitigating risk, cost, and manpower

The “CUBE” Filter Press

- Completely modular, bolt on system that can be adjusted to meet almost any throughput demands

- Utilizes HPT (“High Pressure Technology”) to turn the liquid ash slurry product into a dry mud “cake” that can be easily handled

- Operates in a controlled environment utilizing dredging and pumping instead of trucking

- The technology requires no civil works projects to install on site

Benefits

- Cost Effectiveness

- Dredging and Pumping vs Excavation and Trucking

- Processing systems located at target (landfill) vs source

- Wet screening at target destination eliminates a huge cost component

- Risk Mitigation / Safety

- Dramatic reduction in manpower and moving parts

- Hard pipe contaminant material and closed circuit operation

- Simple scalability without footprint disturbance

Results

- Post process water is free of suspended solids

- End product, dry mud “cakes” contain a target moisture of less than 20%

- These “cakes” are easily handled and conveyed after being removed from the filter press system